Soundproofing Barrier Panels

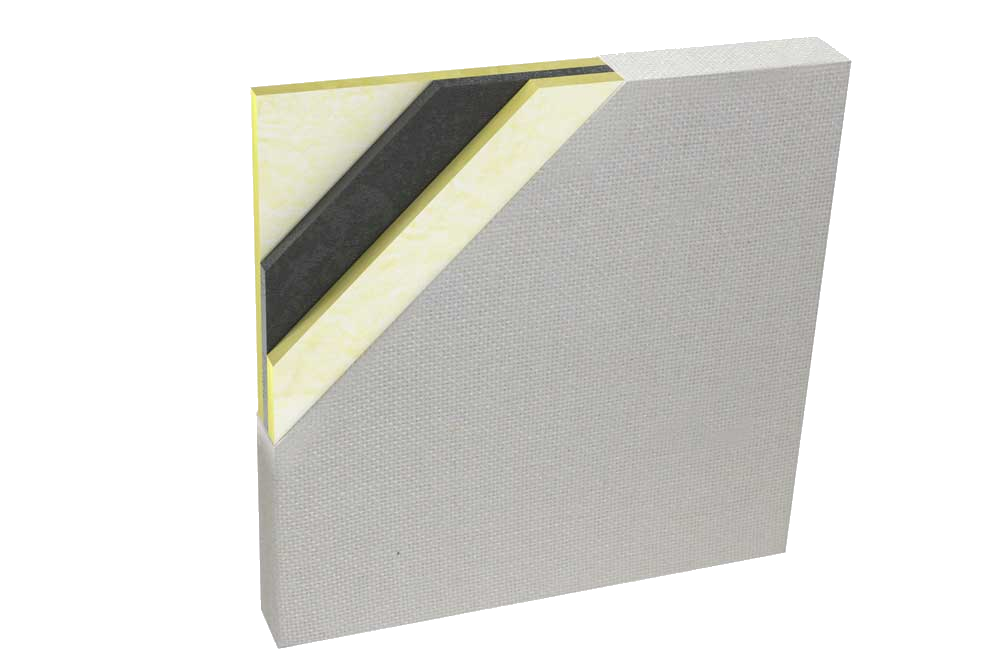

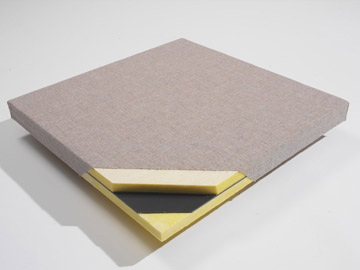

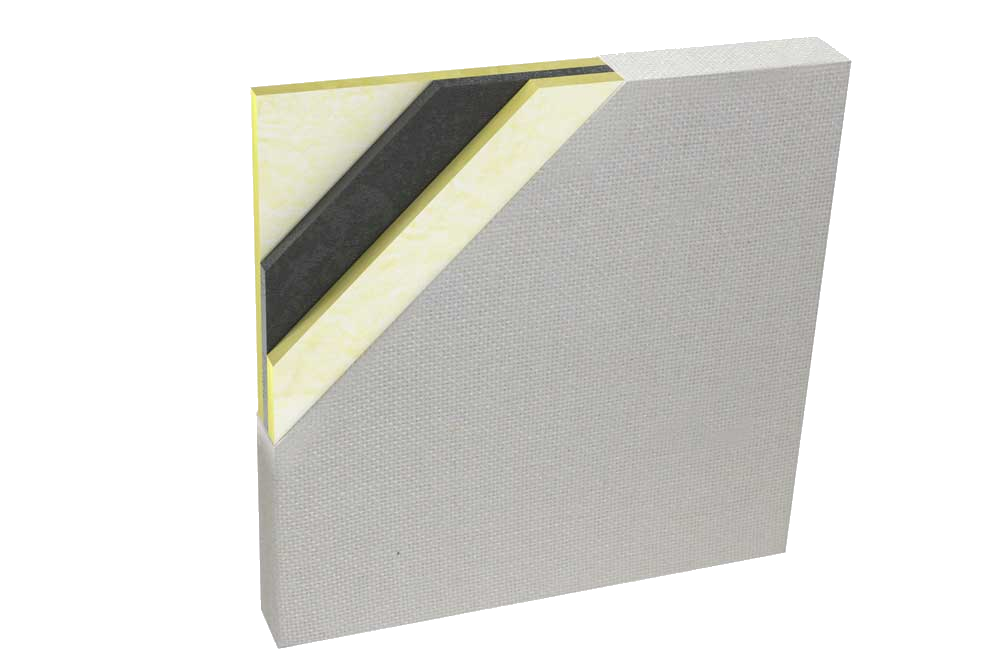

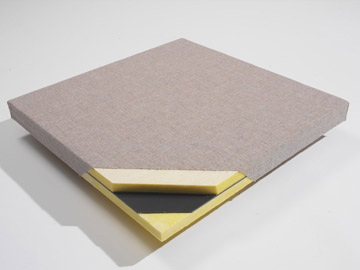

All of our acoustic panels are designed to “absorb” echoes within a room to lower the level of background noise and make the room sound better. However, most acoustic panels do little to combat sound bleeding through the wall to an adjoining room. The one exception to this rule is our FabricBloc soundproofing panel. These are a hybrid sound absorbing wall panel that combines to both “block” noise from bleeding through your common wall to the adjoining room, as well as “absorb” echoes reflecting back off the wall into your same room. FabricBloc panels are constructed by sandwiching a layer of our dB-Bloc between two 1″ thick Fabric Panels. The resulting panel is 2-1/8″ thick.

Questions? Call 1-800-638-9355

The Right Solution

The goal with FabricBloc Panels is to isolate one room’s noise from an adjacent room without needing to re-drywall the surface. FabricBloc soundproofing panels can easily be affixed to any existing finished surface, or be recessed into any new build or remodel project where sound isolation is a must.

These sound absorbing wall panels are available in 44 color options, and we will cut them to match the cavity size of your common wall surface. Care should be given to cover 100% of the common sound barrier wall, or the noise will bleed around it and through to the next room over. Color chart listed below. Free color swatches upon request!

Pricing

For our FabricBloc Panels to be effective at blocking sound, 100% surface coverage is required. Due to this, FabricBloc Panels are custom-quoted on a per-project basis. Note that you can have us cut the panels to any size required for your treatment up to a maximum size of 4′ x 10′. All FabricBloc soundproofing panels are shipped with square edges that are not resin-hardened so they can “squish” together to create a tight seal between adjacent panels.

Questions? Call 1-800-638-9355

Case Study

Discover how FabricBloc sound-blocking panels transformed a college music department by acoustically separating a row of practice rooms. This case study highlights how our panels effectively reduced sound transfer, allowing musicians to practice without disturbing adjacent rooms. If you’re looking for a proven solution to control noise in your space, check out the full story to see FabricBloc Panels in action.

View Case Study

Tips & Techniques

The purpose of the FabricBloc Panel treatment is to provide sound isolation between two adjacent rooms without having to renovate the existing walls. Usually, only one side of the wall needs to be treated. The panels should go on the side of the wall that is producing the most sound. If the room has a drop ceiling, you may also need to add Ceiling Caps to prevent sound from passing through through the ceiling plenum.

Questions? Call 1-800-638-9355

See Ceiling Caps

Sound Test Results

FabricBloc Sound-Blocking Acoustic Panels – FAQs

What are FabricBloc panels?

FabricBloc panels are high-performance acoustic panels designed to block and absorb sound, reducing noise transfer between spaces while improving room acoustics.

How are FabricBloc panels different from standard acoustic panels?

Unlike traditional acoustic panels that primarily absorb sound, FabricBloc panels include a sound-blocking core that prevents sound from passing through, making them ideal for separating noisy spaces like music rooms, offices, and conference areas.

Where can FabricBloc panels be used?

These panels are commonly used in music practice rooms, conference rooms, offices, recording studios, classrooms, and other spaces where sound transfer needs to be minimized.

How effective are FabricBloc panels at blocking sound?

FabricBloc panels provide significant sound reduction, helping prevent noise from transferring through walls. Their in-field performance depends on installation and elimination of acoustical flanking paths, but they are a proven solution for reducing noise bleed between spaces.

Can FabricBloc panels be customized?

Yes! FabricBloc panels are available in various sizes, thicknesses, and fabric finishes to match your design needs. You can choose from a wide selection of fabric colors and textures to blend seamlessly with your space.

How are FabricBloc panels installed?

They can be wall-mounted using standard mounting hardware. Depending on your needs, they can be directly adhered to the wall with impaling clips, or mounted using Rotofast snap-on anchors. Remember, they are heavy, so the bottom edge of the panels should be supported by the floor or a secure furring strip.

Do FabricBloc panels help with echo and reverberation?

Yes! While their primary function is blocking sound, they also have an absorptive surface that helps reduce echo and improve speech clarity in a room.

Can these panels be used on ceilings?

FabricBloc panels are designed for walls, but if you need ceiling-mounted solutions, we offer other acoustic ceiling treatments that complement FabricBloc panels.

Are FabricBloc panels fire-rated?

Yes! Our FabricBloc panels meet ASTM E84 Class A fire rating standards, making them safe for use in commercial and institutional settings.

How do I clean and maintain FabricBloc panels?

FabricBloc panels are low-maintenance. Regular dusting or light vacuuming is usually sufficient. For spills or stains, spot-clean with a mild detergent and water.

How can I get a quote or learn more?

You can contact us for a free consultation to discuss your project’s needs. Our team can help you determine the best panel sizes and configurations for your space. Contact us Today!

Installation and Shipping

FabricBloc Panels will ship with a set of mechanical clips that can be used to easily anchor the panels to your wall. These sound barrier panels will be heavy, so they need to be supported by the floor, the clips are there simply to hold the panels against the wall. The density of the panels is what gives them their sound-blocking properties. They will be carefully packaged and edge protected, shrunk wrapped on pallets, and shipped to your project site. Be sure to inspect the order upon delivery and sign for anything that may appear to have been damaged in transit.

Shipping/Receiving Terms & Conditions